KAP-ZiLO / KAP-ELO

Openings for doors and windows in an easy way

Basic

The double (twin) wall

The double wall convinces more than ever and is enjoying a growing popularity. Similar to the floor slabs in the past the use of the double wall is sharply increasing because it substitutes cast- in- place concrete walls. Not only the high surface quality but also through the possibilities of the exact production- and quality control as well as the quick construction process it´s unimaginable to do without the double wall in today´s construction. In particular the high cost-effectiveness and quality characterize the modern double wall.

As a highly flexible system block the double wall is used in business-, industrial-, and commercial buildings for basement walls, floor walls, staircase walls and fire protection walls. In so doing the double wall represents a real alternative to cast-in-place concrete and other types of wall.

Innovation

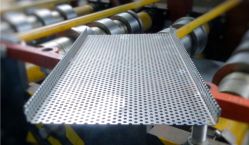

Perforated steel replace wooden formwork

The perforated steel formwork from Kappema:

- KAP-ZiLO: Made from galvanized perforated steel

- KAP-ELO: Made from perforated stainless steel

Both opportunities are available till a wall size of 50 cm

The perforated steel sheet was designed that it remains only 3 till 5 mm on behind of the opening in the concrete. So it´s easy to plaster the soffit after filling concrete.

The work intensive stiffen of each opening before filling concrete is no more necessary. All openings are ready for filling concrete. On construction side every door can be passed by which shorten the ways and working time.

Product

Product

KAP-ZiLO and KAP-ELO

The perforated steel sheet is bend and folded. Available in every length you need. With this openings can be done in one piece.

To make an angle the perforated steel sheet is cut at the fold and then bend over an edge in any angle you wish. No special tools are needed.

Processing

At production

To simplify the work flow in production KAPPEMA created magnet holders which ensure the exact height on the table.

The openings are done with the normal steel formwork system. Course of this all edges are with a clear 45° edge.

After placing the reinforcement the magnet holders are placed on top of the steel formwork and the perforated steel is fixed also on side with magnets easily. After placing the perforated steel sheet the concrete can be filled up. The second layer will be finished completely with formwork, reinforcement and concrete.

The perforated steel which is now fixed in the concrete from the first layer goes directly into the wet concrete near the formwork. After hardening the perforated steel is completely fixed in both layers and no additional work is necessary. Also not for the construction company.