How fast it´s possible to fill up wall elements with KAP-Steel-Wave?

|

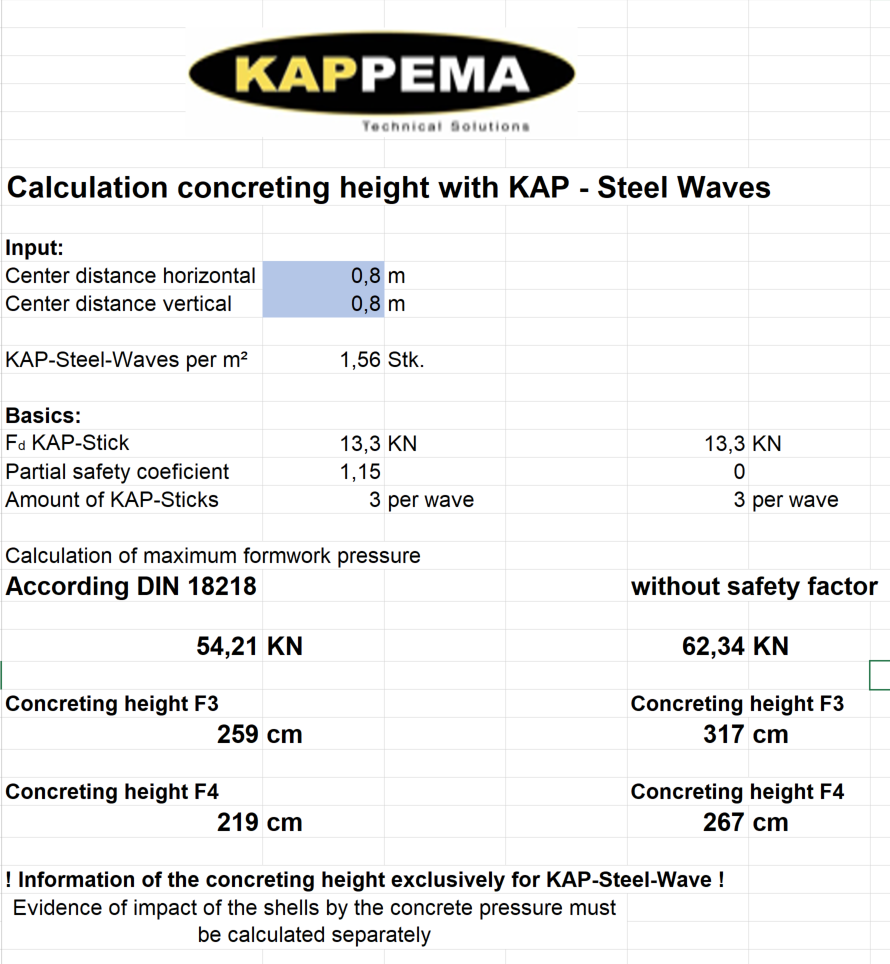

Like all other double wall systems on the market the speed for filling the concrete in the element depends on the numbers of connectors between the layers, the possible force against pull out and the hydrostatic pressure of the concrete on the other side which is calculated out of the filling high and consistency.

Using a lattice girder system in the double wall you will find normally a maximum speed of 80 cm height per hour. Calculating the filling time for a normal cellar you will have round three hours which means high costs for labor and concrete pump as well as ready mix truck. It is possible to speed up if you place the lattice girder with smaller distance but it will also increase the costs on material.

The KAP-Steel-Wave is fixed with the patented stick in complete length in the layer. Course of this it has a much higher resistance against the pull out and much more forces can be taken. At the tests which were done for approval it wasn´t possible to pull out the sticks from a 55 mm layer. The stick collapse by a steel cut. By using all reducing factors for calculation of the global safety factor it remains still a possible force of 13.3.5 KN per stick, means 39.9 KN per wave. According the distances between the waves in horizontal and vertical direction you can calculate now the possible filling height per hour. If you use the maximum distance and consistency F3 for the concrete it is possible to fill up 2.59 meter per hour. (the calculation for the resistance of the layer must be done on top) This means a normal cellar can be filled up with concrete in one hour. This will reduce the costs additional to the lattice girder of 66%.

Bigger filling height can be reached at any time very simple by reducing the distance between the waves. Even you can fill up with other consistency of concrete if the calculation is done in advance. We recommend that it´s always necessary to calculate also the stiffness of the layer according the expected hydraulic pressure from the filling concrete.

Course of the high extraction forces of the KAP-Stick the producer will minimize the burst of the double wall elements. The KAP-Stick is always covered in the complete layer over the whole length and provide from production mistakes course of less concrete cover like on a lattice girder. Till today we were not informed about a failure of a KAP-Wave over all the years. We got only the information that a layer get bend after filling a wall up to 4 meter in one hour. But the stick was still fixed in the concrete.

|

|